Yamaha Kt100j Service Manual

- Yamaha Kt100j Engine Manual eBooks Yamaha Kt100j Engine Manual is available on PDF, ePUB and DOC format. You can directly download and save in in to your device such as.

- EBooks Lovebirds Owners Manual And Reference Guide Pdf are currently available. Sheet houghton mifflin yamaha kt100j service download lovebirds owners.

Feb 1, 2012 - YAMAHA KT100J. (v) It is permissible to repair/replace the connector for both CDI and TCI modules. Rule 25.17 of the AKA Manual.

. RACING KART OWNER’ S SERVICE MANUAL 7YP-28199-SE.

It is not possible to put an entire mechanic's education into one manual, so it is assumed that persons using this book to perform maintenance and repairs on Yamaha racing kart have a basic understanding of the mechanical concepts and procedures inherent in racing kart repair technology. HOW TO USE THIS MANUAL CONSTRUCTION OF THIS MANUAL This manual consists of chapters for the main categories of subjects. (See 'Illustrated symbois') This is a chapter with its symbol on the upper right of each page.

1st title This title appears on the upper of each page on the left of the chapter 2nd title symbol. ILLUSTRATED SYMBOLS (Refer to the illustration) SPEC INFO GENERAL INFORMATION SPECIFICATIONS REGULAR INSPECTION AND ADJUSTMENTS INSP ENGINE CARBURETOR ELECTRICAL CARB ELEC Special tool Oil capacity Lubricant Tightening Specified value, Service limit Resistance (Ω), Voltage (V), Electric current (A) Engine speed Apply engine mixing oil Apply lightweight lithium-soap base grease Apply locking agent (LOCTITE. INDEX GENERAL INFORMATION INFO SPECIFICATIONS SPEC REGULAR INSPECTION INSP AND ADJUSTMENTS ENGINE CARBURETOR CARB ELECTRICAL ELEC. CONTENTS REMOVING THE CLUTCH ・・・・・・・・・・・・・・・・・・・・・・・・・ REMOVING THE CRANKSHAFT ・・・・・・・・・・・・・・・・・・ CHAPTER 1 GENERAL INFORMATION REMOVING THE BEARING ・・・・・・・・・・・・・・・・・・・・・・・・ CHECKING THE ENGINE PARTS ・・・・・・・・・・・ INCLUDED PARTS ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ CHECKING THE CYLINDER HEAD ・・・・・・・・・・・・・・・ SWITCH BRACKET ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・ 4-10 CHECKING THE CYLINDER ・・・・・・・・・・・・・・・・・・・・・ INSTALLING THE BATTERY ・・・・・・・・・・・・・・・・・・・・・・・. INCLUDED PARTS INFO INCLUDED PARTS SWITCH BRACKET Install the switch stay between the steering wheel and its support.

Switch button side INSTALLING THE BATTERY 138mm 4-φ6.5 1. Install: Battery box ● 113mm 2. Install: Battery ● 3. Connect: Battery lead ●. STARTING INFO STARTING STARTING THE ENGINE 1. Start the engine by pushing the start switch If the engine fails to start by pushing the start switch, release the switch, wait 30 seconds, and then try again. CAUTION: Do not crank the engine more than 4 seconds ●.

B: 0.03 mm or less D:45.8∼45.9mm Piston: Piston to cylinder clearance 0.030∼0.035mm Type Plain type (Cr-plated) End gap 0.4∼0.5mm Carburetor: KT100SEC Type WALBRO WB-21 Standard setting Idle needle 1-1/3±1/6 (80±10 min.) High speed needle 5/12±1/6 (25±10 min.) Carburetor: KT100SEJ Type. SPEC ELECTRICAL SPECIFICATIONS ELECTRICAL SPECIFICATIONS Battery: Type GT7B-4 manufacturer GS yuasa Operation voltage Rating 6.5Ah Starter motor: Type 5M05-289 manufacturer Mitsuba Operation voltage Output 0.3kw Starter relay: Type B768042 manufacturer Jideco Voltage rating DC12V (30 min.) Min.

Operation voltage DC8 V or less Open voltage DC4 V or less Coil resistance. Remarks Thread N・m(kg・m) Pitch diameter Cylinder head 1.25 18∼23 (1.8∼2.3) Spark plug 1.25 15∼25 (1.5∼2.5) Crankcase YAMAHA Bond No. 1215 10∼16 (1.0∼1.6) Crankcase cover1 10∼16 (1.0∼1.6) Crankcase cover2 6∼9 (0.6∼0.9) Stay1 mounting bolt 10∼16 (1.0∼1.6) Gear3 mounting bolt 6∼9 (0.6∼0.9).

SPEC CABLE ROUTING DIAGRAM CABLE ROUTING DIAGRAM Starter relay Sub lead Positive lead 1 (battery - starter relay) Starter switch Positive lead 2 (starter relay - starter motor) Engine stop switch Negative lead 1 (battery - coupler) Fuel hose Negative lead 2 (coupler - starter motor) Throttle cable. INSP MAINTENANCE INTERVALS MAINTENANCE INTERVALS After Every Every Every Every Storage break-in race third fifth required Item Remarks (or 100 km) (or 300 km) (or 500 km) (or 1000 km) CYLINDER HEAD Inspect ○ ○ Clean ○ Carbon deposits Tightening ○. INSP MAINTENANCE INTERVALS After Every Every Every Every Storage break-in race third fifth required Item Remarks (or 100 km) (or 300 km) (or 500 km) (or 1000 km) CARBURETOR Inspect (Needle adjuster) ○ ○ Standard position (Metering lever) ○ ○ Bend/spring free length Clean ○. INSP ENGINE ENGINE ADJUSTING THE ENGINE IDLING SPEED 1.

Adjust: Idle needle ● Turning in the idle needle screw will lean out the mixture at low speeds, and turning out it will enrich the mixture. Standard idle needle screw position SEC:. INSP ENGINE ADJUSTING THE THROTTLE PEDAL 1. Inspect: Throttle pedal free play ● Throttle pedal free play 2∼5mm Out of specification → Adjust. Adjust: Throttle pedal free play ● Loosen the locknut and turn the adjuster ・ in fully.

INSP ELECTRICAL ELECTRICAL CHECKING THE BATTERY WARNING Batteries generate explosive hydrogen gas ● and contain electrolyte which is made of poisonous and highly caustic sulfuric acid. Therefore, always follow these preventive measures: Charge batteries in a well-ventilated area. INSP ELECTRICAL NOTE: Since MF batteries are sealed, it is not possible to check the charge state of the battery by measuring the specific gravity of the electrolyte. Therefore, the charge of the battery has to be checked by measuring the voltage at the battery terminals. INSP ELECTRICAL NOTE: The charge state of an MF battery can be ● checked by measuring its open-circuit voltage (i.e., the voltage when the positive terminal is disconnected).

No charging is necessary when the open- ● circuit voltage equals or exceeds 12.8 V. INSP ELECTRICAL CAUTION: Never remove the MF battery sealing caps. ● Do not use a high-rate battery charger since it ● forces a high-amperage current into the battery quickly and can cause battery overheating and battery plate.

If it is impossible to regulate the charging ●. INSP ELECTRICAL 5. Inspect: Battery terminal ● Dirt → Clean with wire brush Loose → Connect 6. Apply the grease.

Battery terminal ● 7. Install: Battery ● 8. Connect: Battery lead ● (to battery terminal) CAUTION: First, connect the positive lead, then the negative lead. INSP ELECTRICAL CHECKING THE SPARK PLUG NOTE: Remove a mud and dust from the cylinder head before removing the spark plug.

Inspect: Electrode ● Wear/Damage → Replace. Dirt/Carbon deposit → Clean the spark plug with a spark plug cleaner or wire brush. Wear/Damage →. INSP ELECTRICAL CHECKING THE IGNITION TIMING 1.

Remove: Spark plug ● Crankcase cover2 ● Gear3 ● Stay1 ● 2. Attach: Dial gauge stand set ● Dial gauge stand set 2 3. Rotate the rotor counter clockwise until the piston reaches top dead center (TDC). INSP ELECTRICAL ADJUSTING THE COIL GAP 1. Remove: Crankcase cover2 ● Gear3 ● Stay1 ● 2. Measure the air gap between the rotor ・ and coil assembly Standard air gap 0.4mm Out of specification → Adjust.

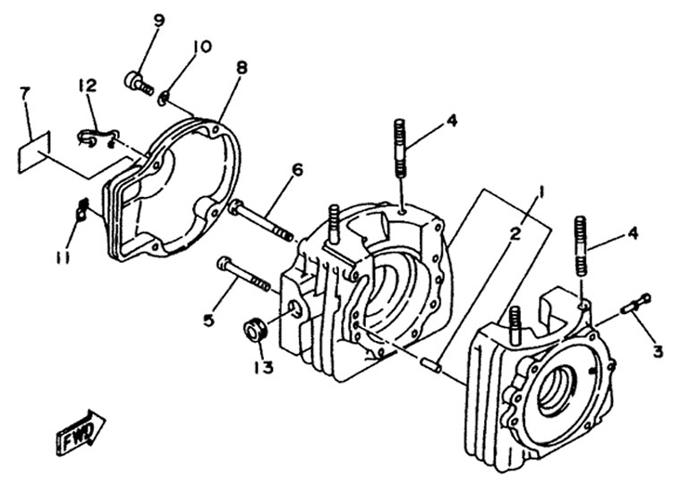

Adjust: Air gap ●. EXPLODED DIAGRAM EXPLODED DIAGRAM ENGINE Bearing Crankcase (L, R) Cylinder head Oil seal Joint pipe Cylinder head gasket Small end bearing Drive sprocket Spark plug Piston pin Cylinder Piston Absorber A Cylinder gasket Piston ring Absorber B Crank assembly Piston pin clip. EXPLODED DIAGRAM TCI MAGNETO STARTER MOTOR Engine starter switch Gear1 Rotor Crankcase cover1 Engine stop switch Coil assembly Crankcase cover2 Needle bearing Lead wire Starter motor Bearing Plate Idle gear Gear3 Needle bearing Stay1. EXPLODED DIAGRAM SL CLUTCH ASSY Circlip (seeger ring) Stud bolt (adapter shaft) Spacer Thrust washer (shim) Sprocket Z10 Clutch body Sprocket Z11 Key (woodruff key) M5 screw Clutch cover Clutch drum Chain guard Roller gauge M8 stopper screw (stop dowel).

DISASSEMBLING THE ENGINE DISASSEMBLING THE ENGINE REMOVING THE CYLINDER HEAD AND CYLINDER 1. Remove: Spark plug ● Cylinder head mounting nut ● Cylinder head ● 2.

Remove: Cylinder head gasket ● Cylinder mounting nut ● Cylinder ●. DISASSEMBLING THE ENGINE 3.

Remove: Piston ring ● While opening its meeting ends, remove the piston ring on the side opposite to them. CAUTION: Take care not to scratch the piston or damage the piston ring by expanding it more than necessary. DISASSEMBLING THE ENGINE 2. Remove: Rotor ● When removing the rotor, use the rotor puller Rotor puller 2 CAUTION: Take care not to screw in the two bolts of the rotor puller too far. They may contact the stator and damage it. DISASSEMBLING THE ENGINE 4.

Yamaha Kt100j Owners Manual

Loosen: M8 stopper screw (stop dowel) ● Stud bolt (adapter shaft) ● 5. Remove: Clutch body ● Reference For removal, use the specialized tool. Remove: Key (woodruff key) ● REMOVING THE CRANKSHAFT 1. DISASSEMBLING THE ENGINE 2. Remove: Bolt (crankcase) ● 3.

Remove: Right crankcase ● Make sure the crank separating tool body is parallel with the crankcase. Crankcase separating tool: 5 CAUTION: Take care so that the oil seal lip is not damaged. CHECKING THE ENGINE PARTS CHECKING THE ENGINE PARTS CHECKING THE CYLINDER HEAD 1. Inspect: Carbon deposits ● Use a rounded scraper CAUTION: Avoid scratching the aluminum. Measure: Cylinder head warpage ● Warp limit 0.015mm Out of specification → Replace.

CHECKING THE ENGINE PARTS CHECKING THE CYLINDER 1. Inspect: Exhaust port carbon deposition ● Use a rounded scraper CAUTION: Avoid scratching the aluminum.

Inspect: Cylinder wall ● Score marks → Repair. Use #400∼600 grit wet sandpaper. Damage → Rebore or Replace. CHECKING THE ENGINE PARTS CHECKING THE PISTON AND PISTON PIN 1. Inspect: Piston crown carbon deposits ● Use a scraper.

Ring groove carbon deposits ● Use a used piston ring. Wear/Scratches/Damage → Replace. Measure: Piston diameter ●.;;;;; CHECKING THE ENGINE PARTS CHECKING THE PISTON CLEARANCE Feeler gauge Method to use a feeler gauge. ● Feeler gauge How to insert the piston and the feeler gauge Piston is as shown: The piston pin is inserted in parallel with the crankshaft axis.

CHECKING THE ENGINE PARTS CHECKING THE CLUTCH 1. Inspect: Clutch drum ● Clutch body ● Wear/Scratch/Damage → Replace. Inspect: Drive sprocket ● Wear/Damage → Replace the clutch drum. Inspect: Clutch shoe thickness ● Standard shoe thickness 3.3mm Wear limit Roller gauge.

CHECKING THE ENGINE PARTS CHECKING THE GEAR1, 3 AND IDLE GEAR 1. Inspect: Gear1 ● Gear3 ● Idle gear ● Wear/Damage → Replace. CHECKING THE STARTER MOTOR GEAR 1. Inspect: Starter motor gear ● Wear/Damage → Replace.

CHECKING THE CRANKSHAFT 1. CHECKING THE ENGINE PARTS CHECKING THE CRANKCASE OIL SEAL 1.

Inspect: Oil seal ● Wear/Damage → Replace. CHECKING THE CRANKCASE 1. Inspect: Right crankcase ● Left crankcase ● Wear → Repair.

Use #400∼600 grit wet sandpaper. INSTALLING THE ENGINE INSTALLING THE ENGINE INSTALLING THE CRANKSHAFT 1. Install: Crankshaft bearing ● Install the bearing by pressing it on the side having the manufacture's marks or numbers.

NOTE: Install the bearing with its outer race 0.5mm above the crank case surface. INSTALLING THE ENGINE INSTALLING THE CRANKCASE 1. Clean the contacting surface of crankcase (left and right) before applying the sealant. Install: Dowel pin ● 3.

Install: Right crankcase ● Crankshaft ● Install the crankshaft by installing tools. Crankshaft installing pot 4 Crankshaft installing bolt. INSTALLING THE ENGINE 5. Install: Crankcase mounting bolt ● Tighten all bolts in 2∼3 steps and be sure to tighten in numbered order as shown. Crankcase mounting bolt 1.0∼1.6kg・m 6. Install: Engine bracket ● Engine bracket mounting bolt 2.5∼3.0kg・m INSTALLING THE PISTON RING AND PISTON 1. INSTALLING THE ENGINE 3.

Install: Piston ● Piston pin ● Piston pin clip ● The arrow on the piston dome must point to exhaust side. Piston pin clip NOTE: Before installing the piston pin clip, cover the ●. INSTALLING THE ENGINE 4. Install: Cylinder head ● Cylinder head 1.8∼2.3kg・m Tighten all bolts in 2∼3 steps and be sure to tighten in numbered order as shown.

INSTALLING THE TCI MAGNETO 1. Temporarily install: Plate ● 2.install: Woodruff key ●. INSTALLING THE ENGINE 2. Install: Stay1 mounting bolt ● Stay1 ● Gear3 mounting bolt ● Gear3 ● Gear1 ● Idle gear ● 3. Install: Crankcase cover2 mounting bolt ● Crankcase cover ● INSTALLING THE CLUTCH 1. INSTALLING THE ENGINE 4.

Tighten: M8 stopper screw (stop dowel) ● Apply locking agent (LOCTITE M8 stopper screw (stop dowel) 2.0kg・m 5. Tighten: Thrust washer (shim) ● Roller gauge ● Apply the grease onto the roller gauge. CARB CARBURETOR REMOVING AND DISASSEMBLY THE CARBURETOR Preparation for removal Remove the air box. Remove the fuel hose. ● ● Remove the throttle cable.

Remove the pulse hose. CARB CARBURETOR SERVICE POINTS Clean the removing parts before inspecting. ● Extent of removal REMOVING THE CARBURETOR REMOVING THE METERING DIAPHRAGM REMOVING THE INLET NEEDLE VALVE REMOVING THE PUMP DIAPHRAGM Extent of removal Order Parts name Q'ty Remarks Washer Air box joint1 Gasket Carburetor assembly Gasket. CARB SL CARBURETOR REMOVING AND DISASSEMBLY THE SL CARBURETOR Preparation for removal Remove the air box.

Remove the fuel hose. ● ● Remove the throttle cable. Remove the pulse hose.

CARB SL CARBURETOR SERVICE POINTS Clean the removing parts before inspecting. ● Order Parts name Q'ty Remarks Bolt Manifold Gasket Carburetor assembly Screw Pump cover Pump gasket Pump diaphragm Metering diaphragm gasket Diaphragm assembly Metering diaphragm cover Screw Inlet needle valve Metering lever pin Metering lever Spring. CARB CARBURETOR REMOVAL POINTS REMOVING THE CARBURETOR 1. Disconnect: Fuel hose ● Negative pressure hose ● Throttle cable ● WARNING Plug the fuel hose so that fuel does not run out. NOTE: Always clean up spilled fuel immediately.

CARB CARBURETOR INSTALLING THE CARBURETOR 1. Install: Carburetor ● Air box ● Hose clamp ● Carburetor gasket 2. Connect: Throttle cable ● Fuel hose ● Negative pressure hose ● 3. Adjust: Throttle pedal free play ●.

ELEC WIRING DIAGRAM WIRING DIAGRAM Engine stop switch Engine starter switch White/Black Black Black Black White/Black Black Black Blue White/Black Black Blue Black Battery TCI unit Starter relay Black Black Starter motor Earth. ELEC IGNITION SYSTEM TROUBLESHOOTING 1.

Spark plug Spark plug condition ● NO SPARK Spark plug type ● INTERMITTENT SPARK Spark plug gap ● Check Refer to the CHAPTER 3. Spark plug Standard spark plug 2. Minimum spark gap B9EVX(NGK) 3.

ELEC IGNITION SYSTEM 3. Engine stop switch 5. Secondary coil resistance Check the engine stop switch for continuity. Disconnect the high tension lead from the ● ● spark plug. CONTINUITY Disconnect the spark plug cap from the ● CONTINUITY high tension lead.

Replace the engine Connect the pocket tester (x1kΩ) to the ●. ELEC STARTING SYSTEM TROUBLESHOOTING 2. Starter motor Connect the positive battery terminal ● If the starter motor will not operate. Starter motor lead with a jumper lead Check 1. Starter motor 3. Starter relay 4.

Engine starter switch Black 5. ELEC STARTING SYSTEM 4.

Engine starter switch 3. Starter relay Disconnect the starter relay coupler from Check the engine starter switch for continuity. ● ● sub lead wire. CONTINUITY Connect the pocket tester (x1Ω) and the ● CONTINUITY battery to the starter relay as shown. Replace the engine Battery terminal →.

YAMAHA MOTOR CO., LTD. PRINTED ON RECYCLED PAPER PRINTED IN JAPAN.

Photo 2 To change the case bearings, remove the old oil seals and place the case halves upside-down in the oven (clean it before) to allow the old bearings to fall out. Once the old bearings are removed, put the new ones in place while the aluminum is still hot. Add a bit of 2 cycle oil as case halfs are still warm. Once the case halves are cold, insert bearing grease in the oil seals and put them in place. To ensure a perfect seal, sand the case halves with a 400 grit wet paper. High temperature silicone (Photo 3) should be used to avoid any leak.

Manual Car Service Manuals

Put a tiny layer on each case halves before closing it. Observe the correct bolting sequence. Photo 4 The crankshaft Before installing the new connecting rod, it alignment should be assessed and corrected if necessary.

When rebuilding your crankshaft, great care is required. The crankshaft width will be base on the crankcase width. It should allow an end play between 0.005” to 0.010”. The maximum deflection at each end should not exceed 0.001”.

Cylinder The cylinder must remain stock exept at the intake and the exhaust were it is possible to make some modifications. The height of the cylinder can vary within the technical specifications. Two measures have to be respected. First the cylinder must be low enough to allow the piston to travel at least 1.045” from the top dead center (TDC) to the opening of the highest exhaust port (Photo 4). To measure it, bring the piston to the TDC and put the dial gauge to 0.

Lower the pistion from 1.055” and if a 0.010” filler gauge goes, the cylinder is too high. Second, the piston is only allowed to travel 0.875” from TDC (Photo 5). To avoid excessive wear, the exhaust port bridge must be recessed (approximately 0.0005”).

Evinrude Service Manual

Photo 9 To measure the combustion chamber volume, buy a burette of at least 13cc, fill it with automatic transmission fluid to the zero mark, bring the piston to TDC, and fill the combustion chamber by pouring the fluid through the spark plug hole. The legal minimum limit is 11cc including the spark plug hole. Be aware of the correct bolting sequence. The ignition system The standard gap between the rotor and the stator is 0.020” (Photo 9). The wider the gap, the more retard, and the narrower the gap the more advanced the timing will be.

A wider gap may be preferred for fast tracks, and a narrower gap may be preferred on tighter tracks.