Wellhead Hydraulic Control Panel Vendor Manual

Hydraulic Control Panel For Car Hauler

Petronash is a pioneer with a proven track record in designing, manufacturing, assembling and commissioning of Single-Well, Multi-Well, RTU & PLC-based, SOLAR-powered Wellhead Control Panels (WHCP) for all production fields, including onshore, offshore or artificial islands. Cameron wellhead control panels and surface safety systems feature. Stainless steel 316, NEMA 4X enclosures with integrated hydraulic reservoirs; sequenced.

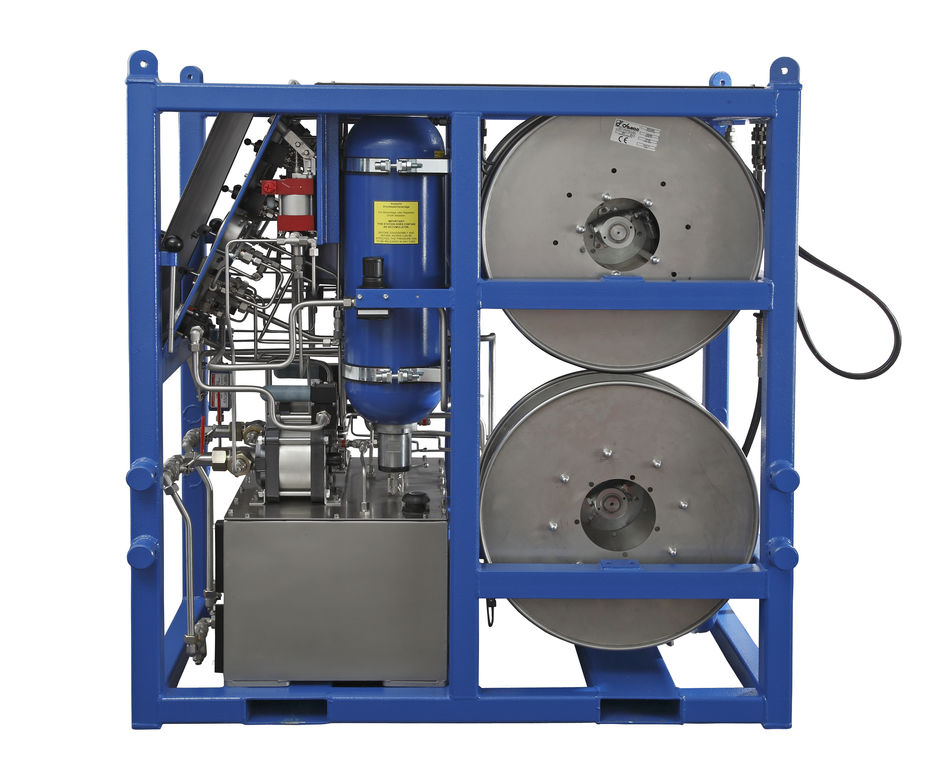

If you are looking for a robust wellhead control system with a strong capacity for controlling components of an oil and gas well, then the DSTM with its two air driven double acting high pressure pumps and two tanks of 100 litres is the right solution for you. The DSTM is a system that has five hydraulic output control lines (5.000 psi) for controlling a downhole safety valve, a spring returned safety valve, a wire line stuffing box and two BOP’s. In addition to its strength, the DSTM provides you with extra backup features like an accumulator BOP backup and a manual backup pump. It also has an audible warning air horn that operates whenever the DHSV, MV, WV or air lines fall below their preset pressures. Which benefits reliable and safe working operations in the oil and gas environment.

Easy operating via engraved panel layout. Large capacity air-driven pumps. Manual backup pump. Fully stainless steel crash-frame Robust and solid design Another main asset of the DSTM is its design that will prove itself under severe conditions in the field, because all components, including the necessary connecting materials and tubing are built together in a crash frame with an offshore coating. Although the DSTM is a robust and solid device, you can be flexible in where you want to place the DSTM as it is possible to move it to another location with a forklift truck. Furthermore, the control panel is equipped with an engraved layout that makes it easier for the operator to control the components of the well.

Petronash is a pioneer with a proven track record in designing, manufacturing, assembling and commissioning of Single-Well, Multi-Well, RTU & PLC-based, SOLAR-powered Wellhead Control Panels (WHCP) for all production fields, including onshore, offshore or artificial islands. Our WHCP's are engineered and built in line with customer specifications and international standards. We have the know-how and proficiency with state-of-the-art technologies, from conventional (Pneumatic/Hydraulic) designs to programmable logic controller (PLC) solutions that can not only meet but also exceed customers’ stringent requirements. We offer compact solutions to complex process needs.

Hydraulic Control Panel Manufacturers

All our WHCPs are user-friendly in terms of operability, maintainability, availability and reliability. WHCPs are also known as Shutdown Panels (SDP) Emergency Shutdown Systems (ESD) Hydraulic Safety Shutdown System (HSSS). These are failsafe shutdown systems which have pneumatic/hydraulic/electric components; WHCPs can also be integrated with PLC/ RTU/ SCADA.

WHCPs are standalone control systems as well as an interface between the plant control and the wellhead safety system. WHCPs are used for monitoring, controlling (Remote/Local) and safe shutdown of Subsurface Controlled Safety Valves (SCSSV), Surface Safety Valves (SSV), and other wellhead safety valves (Choke, ESD, HIPPS) in oil & gas production fields to ensure safe operation of unattended wells/platforms.